Leave your message and you’ll get:

● 24*7 online service support ● Articles in the hair dryer industry ● Sometimes maybe Discount

● 24*7 online service support ● Articles in the hair dryer industry ● Sometimes maybe Discount

Appliance & Electronics Show (Dubai) 2024!

Date: 17–19 December 2024

Time: 10:00–18:00

Booth: AI105

Location: Dubai World Trade Centre

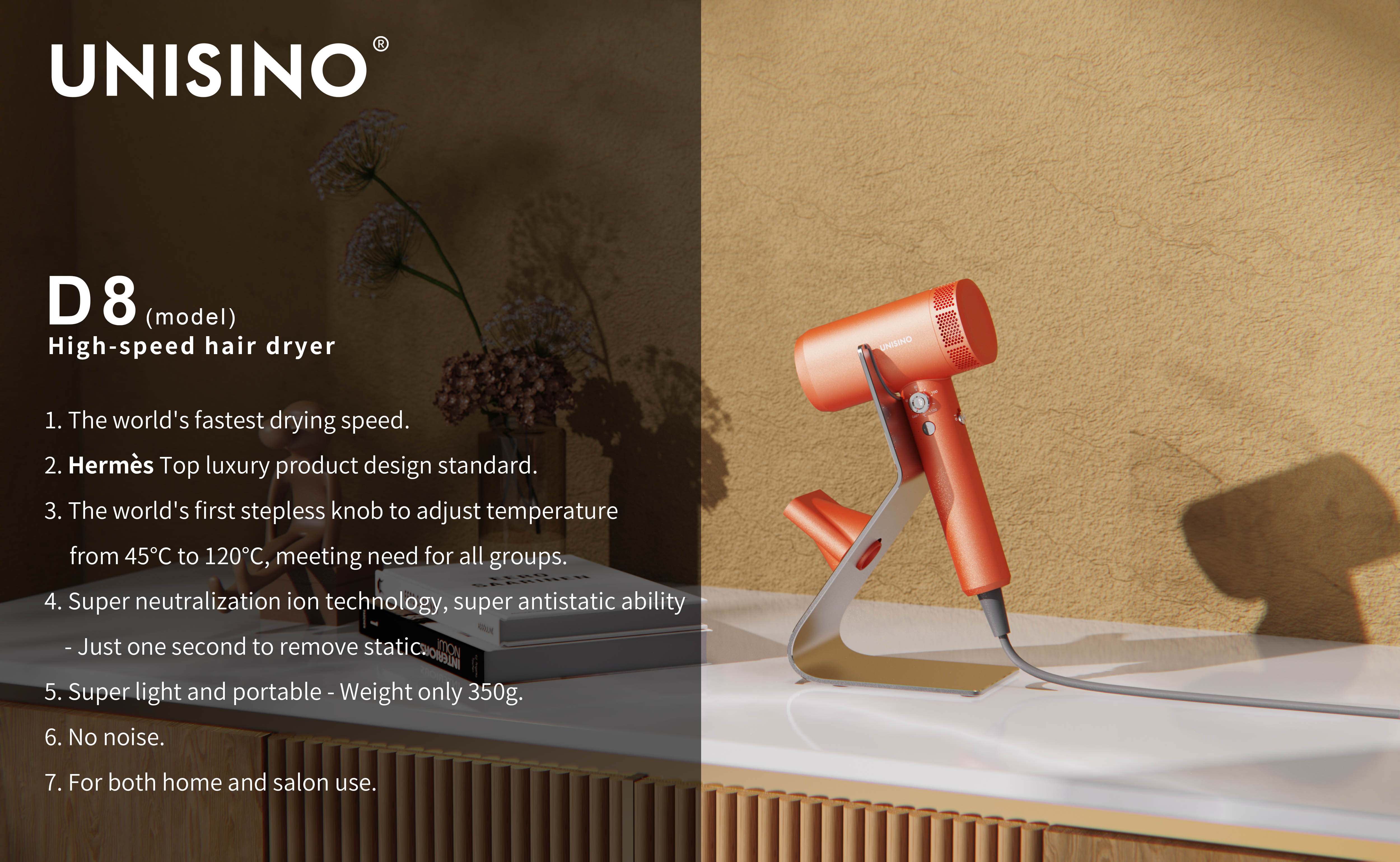

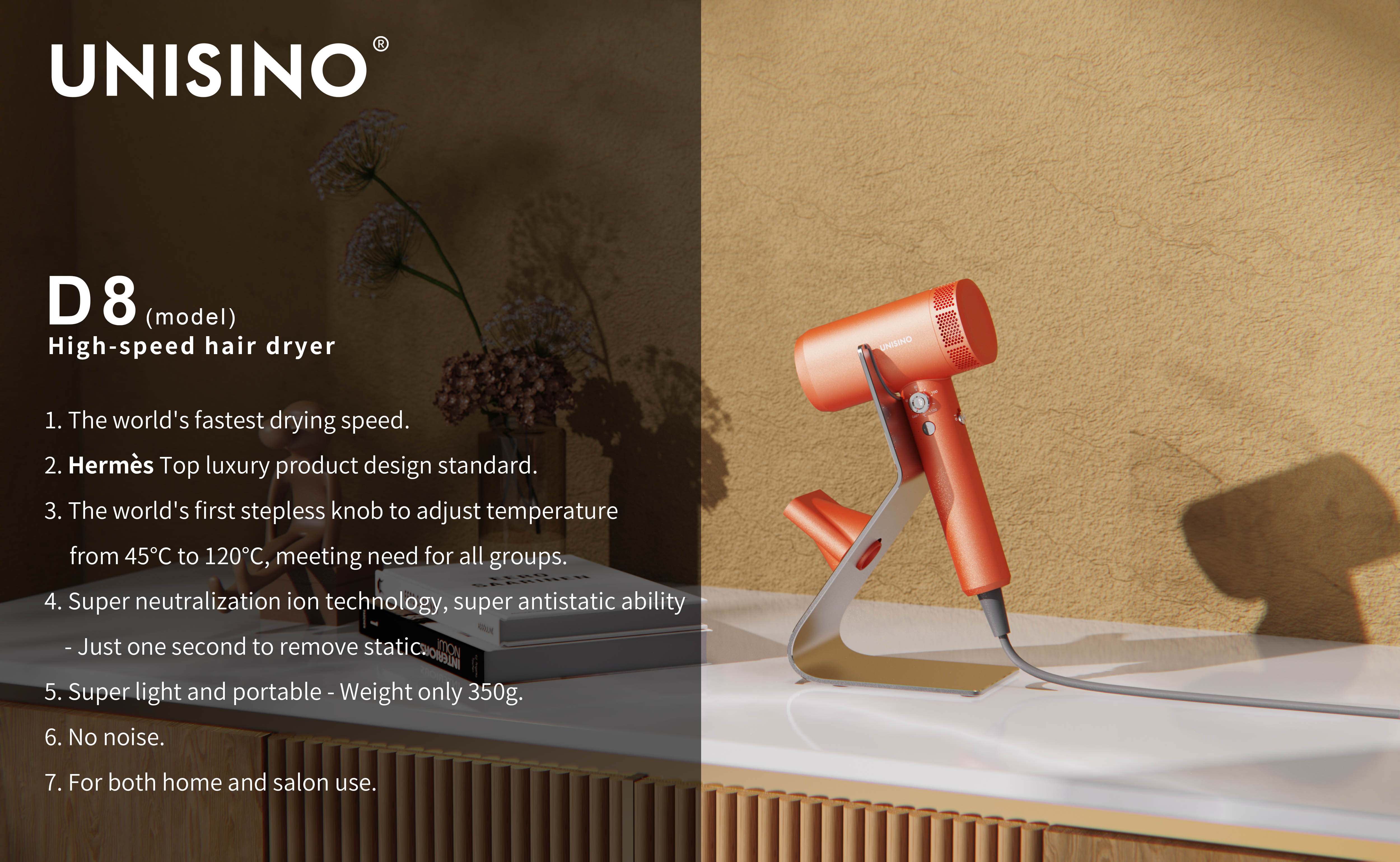

Exciting news from the world of beauty and tech enthusiasts! Our innovative D8 Hypersonic hair dryer made a remarkable debut at the COSMOPROF MIAIMl this January, capturing the interest of brands and distributors from around the globe. This event has set a new standard in hair care technology, emphasizing the D8's revolutionary features and performance.

Read more

Harm 1: Damage to hair quality and scalp health Many inferior unprofessional hair dryers lack the core technologies required for dry hair. When using it, a strong and stable wind speed cannot be produced. It can only dry hair through high temperature baking. The scalp and hair quality will cause major damage under high temperature stimulation for a long time, and serious damage to the hair health. Harm 2: Long -term harm that is difficult to discover Due to the relevant influence of dry hair technology, inferior and unprofessional hair dryers are prone to temperature and unstable wind speed when they are dry. The damage brought by this phenomenon is not easy to detect in the short term, but with the use time, the problem of hair quality will become more and more obvious, and it cannot even be repaired. Harm three: high noise, serious odor In order to control the production cost of the product, many inferior and unprofessional hair dryer manufacturers will choose the quality of

1. Poor quality and high risk of use. Some unprofessional products on the market, including negative ion hair dryers, are often not available in quality, have a short service life, and may also occur. In order to save costs, most of these products use inferior materials, or even recycled waste, leading to poor performance and safety of the product. Moreover, due to the strict quality testing of the product, the production process is rough, and the phenomenon of short -circuit and fire during operation, it will bring bad experience and harm to users. 2. Damaged hair, beautiful and difficult to protect. Long -term use of unprofessional hair dryers will cause continuous damage to hair, affecting the texture and aesthetics of the hair. Unprofessional hair dryer cannot automatically adjust the wind temperature according to the humidity and temperature of the hair, causing the hair to be overheated or too cold, and it is easy to cause problems such as dryness, frosted, and broken hair.

Is a hair dryer worth buying? In the previous science popularization, we fully understood the advantages of high-quality professional hair dryers, which can complete hair care in a very short time. Through the above explanation, we have learned that low-quality and unprofessional hair dryers have many side effects, but we are not clear about the reasons behind these side effects. For this, I have found a hazard analysis data chart for hair dryers to carefully explain the causes of side effects and help everyone avoid inferior products. Reason 1: Overemphasis on marketing, shifting focus of funds Many low-quality brands, in order to gain more profits, often appear to be eager for quick success. For example, they use a large amount of funds to hire celebrities and internet celebrities to promote their products, hoping to open up the market and gain sales. However, this approach results in insufficient funding for product development and upgrades, and consumers who use hair dryers t

At the end of the 19th century, hair dryers were born as reverse applications of vacuum cleaners, with the aim of quickly drying wet hair. For more than a hundred years, regardless of its volume and shape developing towards a more lightweight and ergonomic direction, its basic principle has always been "drying". That is to continuously blow the heated dry airflow towards the wet hair, and the moisture gradually evaporates under the action of the hot air. The drying method has a flaw for consumers with long hair. Due to the drying effect, it is impossible for water to evaporate simultaneously, and it takes a relatively long time to completely dry the hair. This process involves some hair that has already dried, but still needs to be exposed to dry air currents for a long time, which can easily generate static electricity and even turn yellow like hay. So in practical life, many girls with long hair are unwilling to blow dry their hair after washing it, and they also need to leave som

Side effect one: Damage to hair follicles and healthy hair scales Poor quality and unprofessional hair dryers usually have simple construction and limited technical content. Take dry hair as an example, most of them are done at high temperatures. Long term exposure to high temperatures can cause significant damage to hair follicles and scales, leading to problems such as dryness, branching of hair tips, and excessive oil production. Side effect 2: Hidden short-term and difficult to detect long-term damage Traditional low-quality hair dryers are prone to temperature fluctuations and unstable wind speeds when drying hair. In the short term, the harm caused by this situation is difficult to detect. But over time, hair problems such as dryness, dark yellow, and excessive oil production will gradually become prominent, and even cannot be repaired. Side effect three: loud noise and unpleasant odor Due to factors such as production costs and profits, inferior and unprofessional hair

Is a hair dryer worth buying? Whether a hair dryer is worth buying depends on the type of hair dryer. Among them, high-quality professional hair dryers are very worth buying. They can not only dry hair faster and more time-saving, but also maintain hair quality. Nearly 250 million people in our country are troubled by hair loss. A high-quality professional hair dryer that can help us return our hair to a healthy state. Below are the four major advantages of high-quality professional hair dryers. Advantage 1: Protect hair from damage High quality professional hair dryers pay more attention to the maintenance of hair quality and health, so they will choose higher quality and more professional materials and accessories. In terms of motor performance, the running speed of high-quality professional hair dryers is about 5 times that of ordinary hair dryers, with very strong wind speed. Not only can it greatly improve dry hair speed, but it can also avoid hair damage. Advantage 2: Repa