Leave your message and you’ll get:

● 24*7 online service support ● Articles in the hair dryer industry ● Sometimes maybe Discount

● 24*7 online service support ● Articles in the hair dryer industry ● Sometimes maybe Discount

Time:2023-10-21 Views:1

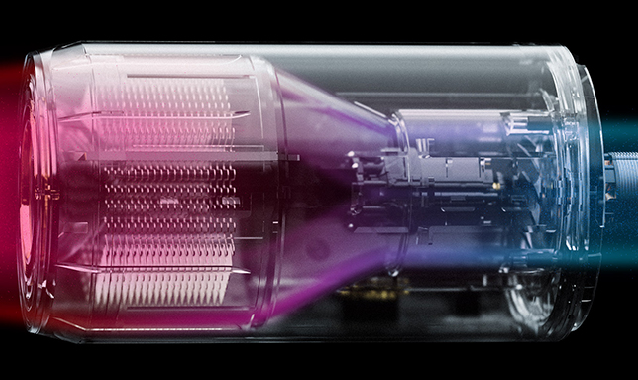

Electric hair dryers are mainly used for hair drying and shaping, but they can also be used for local drying, heating, and physical therapy in laboratories, physical therapy rooms, industrial production, art, and other fields. According to the type of motor used, it can be divided into AC series excitation, AC shield pole, and DC permanent magnet. The advantages of series excited hair dryers are high starting torque, high speed, and suitable for manufacturing high-power hair dryers; The disadvantage is high noise, and the commutator has certain interference with telecommunications equipment. The advantages of a covered pole hair dryer are low noise, long lifespan, and no interference to telecommunications equipment; The disadvantages are low speed, poor starting performance, and heavy weight. The advantages of permanent magnet hair dryers are light weight, high speed, simple manufacturing process, low cost, and good quality at a reasonable price. The specifications of hair dryers are mainly divided by electrical power, and commonly used specifications include 250 watts, 350 watts, 450 watts, 550 watts, 850 watts, 1000 watts, 1200 watts, etc. Although there are significant differences in the types, styles, and sizes of hair dryers, their internal structure is generally the same, mainly composed of three parts: the electric motor and its driving blades, heating elements, and electrical control switches. The combination of an electric motor, fan blades, and casing structural components forms a miniature hair dryer.

With the reform and gradual improvement of the performance of hair dryers, a set of constant temperature automatic electronic control elements have been connected in series to the heating elements of hair dryers both domestically and internationally. It can automatically connect the circuit under normal working conditions of the air duct and cut off the circuit in case of special circumstances such as overheating of the heating element. In terms of the selection of materials for the outer shell of the air duct, the metal (such as copper or cold-rolled iron sheet) material has also been changed to thermoplastic engineering materials (mainly polycarbonate, modified polystyrene, modified polypropylene, etc.). Working principle: Electric hair dryers directly rely on electric motors to drive the rotor to rotate the wind blades. When the wind blades rotate, air is sucked in from the air inlet, and the centrifugal airflow formed by this is blown out by the front nozzle of the air duct. When air passes through, if the heating wire installed on the heating bracket in the air nozzle has been electrified and heated, it blows out hot air; If the selection switch does not energize the heating wire to generate heat, then cold air is blown out. Electric hair dryers are used to achieve the purpose of drying and shaping. The selection switch on the hair dryer handle is generally divided into three positions, namely off position, cold air position, and hot air position, and is accompanied by indicator signs in white, blue, and red colors. Some hair dryers also have a motor speed control switch on the handle for selecting the size of the air volume and the temperature of the hot air. Various types of hair dryers are equipped with a rotating circular air conditioning cover on the back or side of the casing. By rotating the cover to adjust the cross-sectional size of the air inlet, the conveying wind speed and hot air temperature can be adjusted.

According to usage, there are handheld and stand hair dryers. The stand style hair dryer can be placed on a table or hung on a wall for use, and you can blow it yourself. According to the air supply method, there are centrifugal hair dryers and axial flow hair dryers. The centrifugal type relies on an electric motor to drive the fan blades to rotate, allowing the air entering the hair dryer to obtain inertial centrifugal force and continuously exhaust outward. Its disadvantage is that not all the exhaust air flows through the motor, resulting in a higher temperature rise of the motor; The advantage is low noise. An axial flow motor drives the fan blades to rotate, pushing the air entering the hair dryer to flow axially and continuously exhaust air outward. Its advantage is that all the discharged air flows through the motor, which has good cooling conditions and insulation that is not prone to aging; Its disadvantage is that it is noisy. According to the material used for the shell, there are metal type hair dryers and plastic type hair dryers. The metal hair dryer is sturdy and durable, and can withstand high temperatures. Plastic hair dryers are lightweight and have good insulation performance, but they are prone to aging and have poor high-temperature resistance. Although there are many types of hair dryers, their structures are similar, consisting of a shell, handle, motor, fan blade, heating element, wind deflector, switch, power cord, etc.