Leave your message and you’ll get:

● 24*7 online service support ● Articles in the hair dryer industry ● Sometimes maybe Discount

● 24*7 online service support ● Articles in the hair dryer industry ● Sometimes maybe Discount

Appliance & Electronics Show (Dubai) 2024!

Date: 17–19 December 2024

Time: 10:00–18:00

Booth: AI105

Location: Dubai World Trade Centre

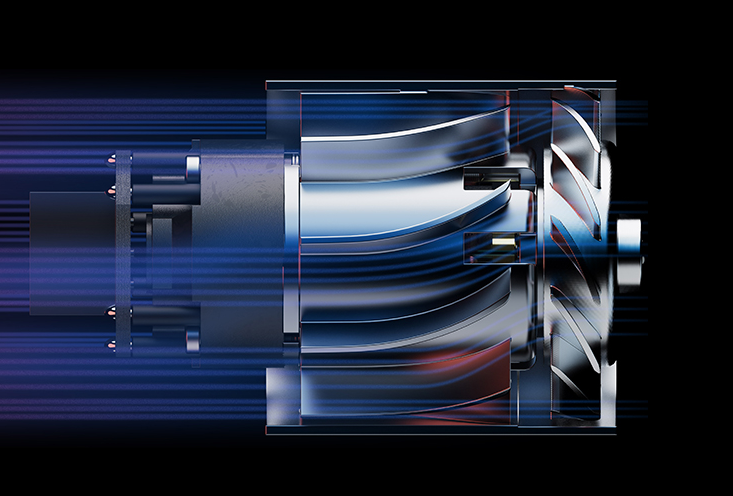

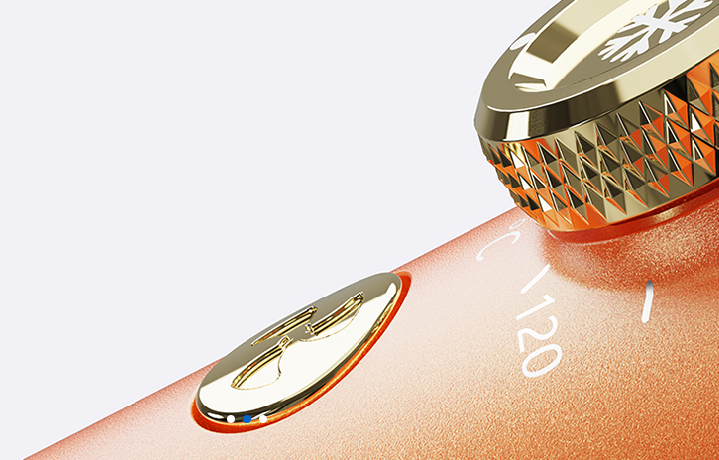

Exciting news from the world of beauty and tech enthusiasts! Our innovative D8 Hypersonic hair dryer made a remarkable debut at the COSMOPROF MIAIMl this January, capturing the interest of brands and distributors from around the globe. This event has set a new standard in hair care technology, emphasizing the D8's revolutionary features and performance.

Read more

1. The health benefits of negative ions on the human body Negative ions are known as "longevity factors" and are beneficial for the treatment of hypertension, asthma, influenza, insomnia, arthritis, burns, and other conditions; It is beneficial for preventing the development of rickets and scurvy, improving lung ventilation function, promoting metabolism, and enhancing immunity. It can also enhance the inhibitory effect of the cerebral cortex and adjust its function; Relax bronchial smooth muscles and relieve their spasms; Slowing down the sedimentation rate of red blood cells and prolonging coagulation time; Strengthen the oxidation of tissues such as the kidneys, liver, and brain. Secondly, since viruses that attack human cells usually carry negative charges, if human cells also carry negative charges, they will be repelled by the same sex. Causes the virus to lose its ability to attack living cells. Finally, negative ions can enter the lungs through respiration and are direct

For those working girls, it is very necessary to choose a hair dryer that suits them, so that after washing their hair in the morning, they can use the hair dryer to blow out the perfect hairstyle. However, the different brands, powers, and functions of hair dryers on the market are also dazzling. So, next, the editor will introduce what hair dryers are good to use and the precautions for hair dryers. 1. When using a hair dryer to blow your hair, it should not be too close to it, as it can easily damage the hair quality and cannot be used for a long time, which can easily cause headaches. Therefore, when using a hair dryer, it is important to keep a certain distance as much as possible. 2. The hair dryer needs to be cleaned regularly because there may be dust accumulation at the inlet and outlet of the hair dryer. However, power should be cut off during cleaning to avoid damage to the hair dryer. Moreover, cleaning the dust in the hair dryer can effectively ensure the health of t

Introduction to negative ion hair dryer Negative ion hair dryer is a type of fine particle that combines negatively charged oxygen with small amounts of water in the air. Once negative ions are adsorbed by the hair, they can penetrate into the hair core and form a moisture protection layer on the surface of the hair, firmly locking in the moisture inside the hair. Negative ions maintain a good balance of moisture in hair for a long time. Is a negative ion hair dryer useful The negative ion hair dryer is mainly equipped with a negative ion generator, so that when the hair dryer is working, it can generate negatively charged ion particles, neutralize the common positive charge in hair, so as to smooth and smooth hair, eliminate static electricity, make hair smoother and easier to comb, and achieve more ideal styling effect. Ordinary hair dryers do not have this effect. Some people have also expressed that if negative ions with negative charges can neutralize positive charges in h

The negative ion converter technology and the nano fullerene negative ion releaser technology can produce ecological level negative oxygen ions that are equivalent to nature. And the negative ion concentration can reach 6 × 107/cm3 or above (i.e. a negative ion concentration of over 60 million per cubic centimeter). Modern medical research has shown that only highly active small particle sized negative oxygen ions can easily penetrate the blood-brain barrier of the human body, exerting their medical and health effects on the human body. Therefore, the emergence of this technology has set a benchmark for ecological negative ion technology, effectively overcoming the technical difficulties of negative ion generators requiring external blowing of fans in the past, and eliminating the noise and electromagnetic radiation of electric fans in the past. 1. The health benefits of negative ions on the human body Negative ions are known as "longevity factors" and are beneficial for the trea

Negative ion hair dryer is a type of fine particle that combines negatively charged oxygen with small amounts of water in the air. Once negative ions are adsorbed by the hair, they can penetrate into the hair core and form a moisture protection layer on the surface of the hair, firmly locking in the moisture inside the hair. Negative ions maintain a good balance of moisture in hair for a long time. The negative ion hair dryer is mainly equipped with a negative ion generator and a semiconductor refrigeration device, so that when the hair dryer is working, it can generate negatively charged ion particles (generated by the negative ion generator) and water vapor particles (generated by the semiconductor refrigeration device), neutralize the common positive charge in the hair, thus smoothing the hair, making it smooth and smooth, and also eliminating static electricity. Make hair smoother and easier to comb, resulting in a more ideal styling effect. The hair dryer heats up during oper

1. When choosing a hair dryer, it is best to choose a hair dryer with double insulation, as its safety will be better than its price. A hair dryer is used in hand, so you can choose a small and lightweight plastic permanent magnet hair dryer. 2. When choosing a hair dryer, it is also necessary to pay attention to its functions, such as having a duckbill style hood that can automatically adjust the temperature of the wind, with negative ion maintenance function, and whether there is an overheating protection device. Is there any noise, odor, or obvious vibration when using it. 3. When choosing a hair dryer, we also need to pay attention to its shell quality, whether its interface is loose, whether its switch is firm and flexible, and whether its packaging information is complete. When choosing a hair dryer, we also need to consider its power and voltage. Generally, the power of a hair dryer used in households is between 600-800W. When purchasing an imported hair dryer, it is impor