Leave your message and you’ll get:

● 24*7 online service support ● Articles in the hair dryer industry ● Sometimes maybe Discount

● 24*7 online service support ● Articles in the hair dryer industry ● Sometimes maybe Discount

Appliance & Electronics Show (Dubai) 2024!

Date: 17–19 December 2024

Time: 10:00–18:00

Booth: AI105

Location: Dubai World Trade Centre

Exciting news from the world of beauty and tech enthusiasts! Our innovative D8 Hypersonic hair dryer made a remarkable debut at the COSMOPROF MIAIMl this January, capturing the interest of brands and distributors from around the globe. This event has set a new standard in hair care technology, emphasizing the D8's revolutionary features and performance.

Read more

1. Prioritize brands with core technologies Famous brands usually focus on product development and technical optimization, with higher requirements for the performance and quality of hair dryers. Therefore, choosing a well-known brand of hair dryer can better ensure the reliability and effectiveness of the product. 2. Choose a hair dryer that can dry hair quickly and maintain a stable wind speed The power and wind speed of a hair dryer determine the efficiency of hair drying. Choosing a hair dryer with higher power and stable wind speed can shorten drying time and reduce damage to hair. 3. Choose a hair dryer with excellent temperature control performance Temperature has a significant impact on hair, and choosing a hair dryer with good temperature control performance can avoid the problem of hair drying and damage caused by excessive temperature. Some high-end hair dryers are equipped with intelligent temperature control technology, which can automatically adjust the temperatu

We have already analyzed the advantages and disadvantages of a hair dryer, and we believe everyone knows that it is necessary to buy a high-quality hair dryer. It can nourish and protect hair from harm. And unprofessional low-quality products can cause hair damage and even pose fire safety hazards. So what are the reasons for the harm of hair dryers? The following is a summary table of negative reviews on hair dryers in relevant forums Reason 1: Insufficient negative ion permeability and poor hair care effect Some brands only stack up the number of negative ions and attract customers with the concept of hair care, but in reality, they do not care or even harm hair. The former, on the other hand, has excellent performance in negative ion quality, purity, concentration, as well as the permeability and output attenuation of negative ions after technical adjustment, in order to effectively nourish and protect hair. Reason 2: The damage rate is extremely high due to parameters such a

What are the advantages and disadvantages of a hair dryer? I understand the benefits of using a hair dryer, but everyone should also be vigilant about its drawbacks and hazards. There are many branded products on the market, and not all hair dryers have these benefits. Some low-quality products not only have no benefits for hair, but also cause hair to be irritable, easily broken, and knotted. Long term use can cause chronic damage to the scalp and hair. So what are the drawbacks of using a low-quality hair dryer? Below, I have summarized four points: 1. Causing dry and easily knotted hair Using a hair dryer for too long or at too high a temperature can cause hair to lose moisture, become dry, and become prone to knots. When hair is in a dry state, it is easy to split and break, and in severe cases, it can even cause hair to fall off. The hot air generated by hair dryers can strip hair of its natural oils, further exacerbating the problem of hair dryness. 2. Hidden Chronic Injur

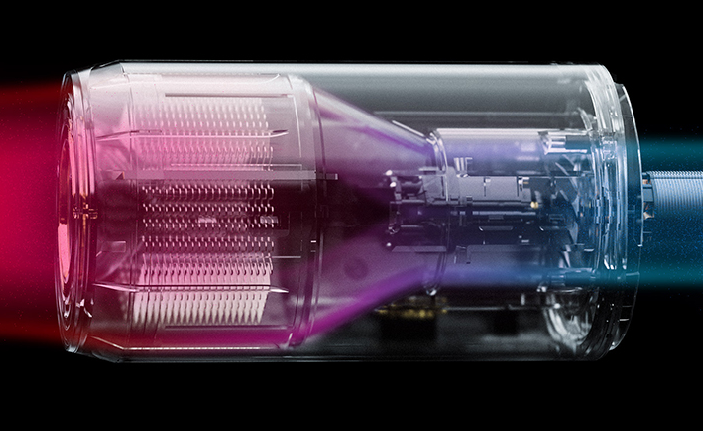

The lifespan of brushless motors is usually longer than that of brushless motors. The brush with a brush motor is a vulnerable component that needs to be replaced regularly. Brushless motors do not have brushes, resulting in a longer lifespan and more reliable and stable performance. In addition, brushless motors have higher operating efficiency and lower energy consumption, which also helps to extend the service life of hair dryers. Is the hair dryer easy to use? Through the full text of popular science, we can learn that a professional hair dryer that has undergone core technology training can not only achieve rapid hair drying, but also better care for hair. Poor quality products can bring serious harm to hair, and even pose safety hazards. Currently, many Chinese people have problems with excessively greasy, matte, and lack of toughness in their hair. The problem of hair damage tends to become younger, so we should avoid the risk of hair damage caused by unqualified products a

A hair dryer is a common electrical appliance in every household, and it can also be said to be essential. Traditional hair dryers blow hair slowly, and after blowing it, it will become hot. Over time, you will find that the hair is rough and irritable, and it is very easy to split. At present, young women have prominent problems such as hair loss, hair loss, hair dryness, and branching, and are showing a rapid trend of youthfulness. The situation for hair maintenance is extremely severe! Using a high-quality hair dryer can effectively improve this issue. The recently popular high-speed hair dryer has received high praise from a large number of netizens. As a hair care professional, I will definitely be the first to evaluate it. What kind of hair dryer is better? The problem of hair loss among Chinese people is becoming increasingly serious, with over 250 million people experiencing hair loss. A user-friendly hair dryer can provide us with a comfortable experience, quickly drying

What kind of hair dryer is good for home use? What should I pay attention to when choosing? This may be a question that many friends have questions about. Don't worry, I have also summarized some shopping tips to avoid everyone stepping on thunder! Collect it quickly. 1. Priority should be given to brands with strong professional strength: Brands with strong technical tuning capabilities will conduct in-depth tuning on some core parameters, such as airflow doubling technology and negative ion penetration technology. Some internet celebrity brands cannot be selected, as their products do not meet the technical standards. 2. Choose one with high wind speed stability: Wind speed stability is influenced by some factors, such as bearings, motors, and brand technology. Fluctuating wind speed can easily damage hair, and long-term use can easily cause chronic scalp and hair damage. 3. Attention should be paid to the loss of hair water diversion: factors such as wind temperature, tempera